No.:201305AC196

Sample Name: extruded sheet

Client:BeijingJinyuntian New Thermal Insulation Building Materials Co. , Ltd

Test Type: sampling inspection

ChinaBuildingMaterials Industrial Technology Supervision andResearchCenter

ChinaBuildingMaterialsIndustryCenterfor Quality Supervision and Inspection of Dry-mixed Mortar

ChinaBuildingMaterials Industrial Technology Supervision andResearchCenter

ChinaBuildingMaterialsIndustryCenterfor Quality Supervision and Inspection of Dry-mixed Mortar

Test Report

No.:201305AC196 Pages: 1/3

|

Name of product |

Extruded sheet |

Type of inspection |

Sampling inspection |

|

Client |

BeijingJinyuntian New Thermal Insulation Building Materials Co. , Ltd |

Date of production |

January, 2013 |

|

Production unit |

BeijingJinyuntian New Thermal Insulation Building Materials Co. , Ltd |

Specifications |

(600×1200×80)mm |

|

Sampling place |

Enterprisefinished-product warehouse |

Trademark |

________ |

|

Sampling person |

Chen Jiayu Su Liang |

Grade |

Grade B2 |

|

Date of sampling |

May 21st 2013 |

Quantity of sampling |

8 pieces |

|

Status of sample |

Clintheriform, in good condition |

Base of sampling |

20m3 |

|

Sampling unit |

ChinaBuildingMaterialsIndustryCenterfor Quality Supervision and Inspection of Dry-mixed Mortar |

||

|

Basis for inspection |

GB/T 10801.2-2002 Extruded Polystyrene Foam Insulation Board (XPS) GB/T 10801.1-2002 expanded Polystyrene Foam Insulation Board |

||

|

Inspection items |

1. Appearance quality 2. Allowable variation 3. Compression strength 4. Water absorption 5. Moisture permeance factor 6. Heat conductivity coefficient 7. Thermal resistance 8. Dimensional stability 9. Combustion performance 10. apparent density |

||

|

Inspection conclusion |

*Through inspection, the inspection results of the appearance quality, allowable variation, compression strength, water absorption, moisture permeance factor, heat conductivity coefficient, dimensional stability and the combustion performance comply with the technical requirements of X150 of GB/T 10801.2-2002. The inspection is conducted according to the test method provided in the Standard GB/T 10801.1-2002. Please refer to the inspection result of apparent density in Page 3. *

Date of issuance: June 18th 2013

(Official Inspection and Test Stamp of China Building Materials Industry Center for Quality Supervision and Inspection of Dry-mixed Mortar) |

||

|

Remarks: (blank here) |

|||

|

Approved by: Reviewed by: Made by: |

|||

|

Address of inspection unit: North Building of China Building Materials, Guangzhuang, Chaoyang District, Beijing Tel: 010-51164723 Postal code: 100024 |

|||

ChinaBuildingMaterials Industrial Technology Supervision andResearchCenter

ChinaBuildingMaterialsIndustryCenterfor Quality Supervision and Inspection of Dry-mixed Mortar

No.:201305AC196 Pages: 2/3

|

No. |

Inspection items |

Requirements (X150) |

Inspection results |

Conclusion |

||

|

1 |

Appearance quality |

Smooth surface without impurities; uniform color; has no visible defects that obviously affect the usage, for example, foam, breach and deformation, etc |

Smooth surface without impurities; uniform color; has no visible defects, for example, foam, breach and deformation, etc |

Qualified |

||

|

2 |

Allowable variation |

Length (1000≤L<2000) |

±7.5 |

-2~+3 |

Qualified |

|

|

L<1000 |

±5 |

-2~+2 |

Qualified |

|||

|

H≥50 |

±3 |

0~+1 |

Qualified |

|||

|

1000≤T<2000 |

≤7 |

3 |

Qualified |

|||

|

3 |

Compression strength, kPa |

≥150 |

160 |

Qualified |

||

|

4 |

Water absorption (soaked in water 96h), % |

≤1.5 |

0.91 |

Qualified |

||

|

5 |

Moisture permeability factor, ng/(ms.Pa) (23℃, RH50%) |

≤3.5 |

2.2 |

Qualified |

||

|

6 |

Thermal conductivity W/(m.K) |

Average temperature10℃ |

≤0.028 |

0.027(average temperature10.00℃) |

Qualified |

|

|

Average temperature25℃ |

≤0.030 |

0.029(average temperature25.00℃) |

Qualified |

|||

|

Remarks: (blank below) |

||||||

|

Address of inspection unit: North Building of China Building Materials, Guangzhuang, Chaoyang District, Beijing Tel: 010-51164723 Postal code: 100024 |

||||||

ChinaBuildingMaterials Industrial Technology Supervision andResearchCenter

ChinaBuildingMaterialsIndustryCenterfor Quality Supervision and Inspection of Dry-mixed Mortar

Test Report

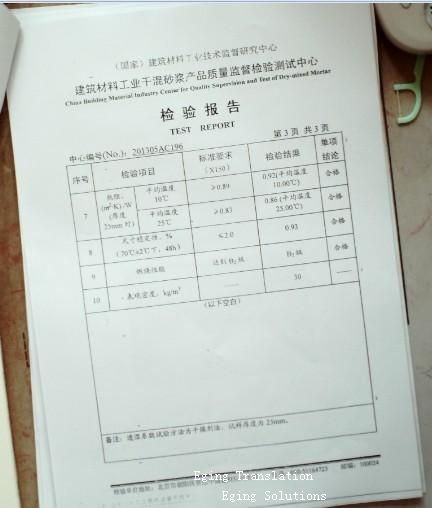

No.:201305AC196 Pages: 3/3

|

No. |

Inspection items |

Requirements (X150) |

Inspection results |

Conclusion |

|

|

7 |

Thermal resistance (m2.K)/W (thickness25mm) |

Average temperature10℃ |

≥0.89 |

0.92 (average temperature10.00℃) |

Qualified |

|

Average temperature25℃ |

≥0.83 |

0.86 (average temperature25.00℃) |

Qualified |

||

|

8 |

Dimensional stability, % (70℃±2℃, 48h) |

≤2.0 |

0.93 |

Qualified |

|

|

9 |

Combustion performance |

Reach Grade B2 |

Grade B2 |

Qualified |

|

|

10 |

Apparent density, kg/m3 |

---------- |

30 |

-------- |

|

|

(Blank below)

|

|||||

|

Remarks: the test method of the moisture permeability factor is the desiccant method and the sample thickness is25mm. |

|||||

|

Address of inspection unit: North Building of China Building Materials, Guangzhuang, Chaoyang District, Beijing Tel: 010-51164723 Postal code: 100024 |

|||||

ChinaBuildingMaterials Industrial Technology Supervision andResearchCenter

ChinaBuildingMaterialsIndustryCenterfor Quality Supervision and Inspection of Dry-mixed Mortar

Test Report

No.:201305AC132 Pages: 4/4

|

Sample Name |

Extruded sheet |

|

(Sample picture)

|

|

|

Remarks: (blank below)

|

|

|

Address of inspection unit: North Building of China Building Materials, Guangzhuang, Chaoyang District, Beijing Tel: 010-51164723 Postal code: 100024 |

|